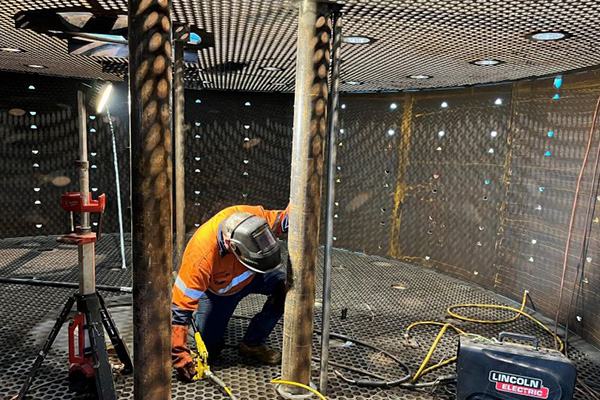

While the focus at this time of year is on the crush, our work execution teams are building major pieces of plant that will be installed once the season ends.

Crews at our Burdekin Centralised Workshop are currently fabricating two new evaporators for Kalamia Mill.

Costed at around $6 million each, the two vessels are among four replacement evaporators being installed at Kalamia over a three-year period.

The first evaporator was fabricated last year and installed ahead of this year’s crush, the two vessels currently under construction will be installed ahead of the 2023 crush, and the fourth new vessel will be installed ahead of the 2024 season.

The total program of works is worth $25 million and is being carried out in-house.

Work Execution Manager Glenn Brock said the major components were being fabricated at Pioneer Mill, while sections of pipe and other structures were being manufactured at Wilmar’s Kalamia, Inkerman and Plane Creek Mill workshops.

“The new evaporators will replace older vessels that have reached end of life. We’re also taking this opportunity to standardise the vessels in the evaporator station in terms of design, construction and capacity,” he said.

“Each of the new evaporators will have a seven metre diameter and a heating surface area of 3250sqm.”

The new evaporators are part of a much larger program to replace end-of-life vessels across all of Wilmar’s eight sugar mills.