More than halfway through the 2025 sugar production season, Macknade Mill's new high-grade fugal station is delivering promising results around improved throughput and sugar quality.

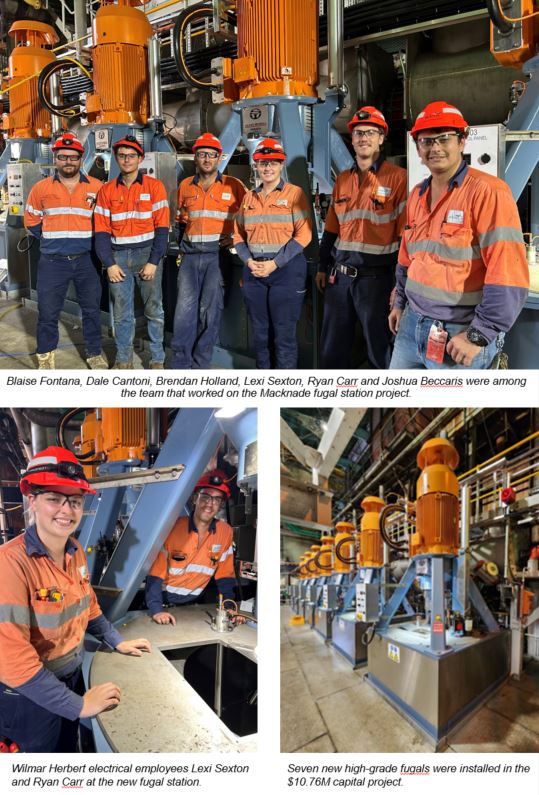

The seven Silver Seibull 1250E fugals were installed during the maintenance season as part of Macknade's largest capital program in a decade.

Senior Project Engineer Joseph Bonassi said the $10.76 million project also included the installation of supporting structure and civil work, a range of new services, and replacement of the fugal and dryer switch rooms.

“Local drainage and access systems were also improved as a portion of the scope of the project, with the aim of improving upon safety culture and factory performance,” he said.

The fugal station is the final stage of the sugar manufacturing process, where a series of centrifuges are used to separate and wash molasses from the sugar crystals.

Macknade Manager Mechanical Engineering Wes Seri said the new fugals were performing exceptionally well.

“From the start of the season there has been a step-change improvement in sugar quality compliance,” he said.

"The old fugal station was traditionally a factory bottleneck when CCS levels were high.

“With the new fugals performing so well, our Operations team is excited for the next few weeks, when CCS is expected to peak.”

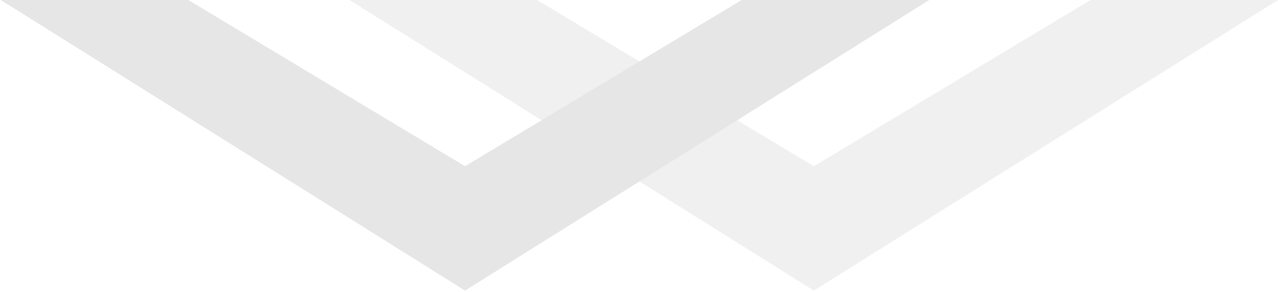

Mr Bonassi said the Herbert Centre of Excellence, site electrical, engineering and technical teams all made significant contributions to the high-grade fugal project.

“The successful delivery of the project reflects the exceptional technical expertise, commitment and collaboration of our people,” he said.

Capital Work Coordinator Joshua Beccaris said the project was delivered on time and budget, despite some unexpected challenges.

“Severe flooding cost us two full weeks of work and presented unexpected hurdles but, thanks to the resilience, adaptability, and commitment of our team, we regrouped quickly, adjusted timelines, and kept the project moving forward without compromising quality,” he said.

“Even with the setbacks, the upgrade was completed efficiently and to a high standard - a true testament to the strength of our people and the value of having skilled talent in-house."

Mr Seri said solid early planning and great teamwork had contributed to the project's success.

“The quality of work was outstanding, reflecting the care and pride our people put into every detail. This achievement speaks volumes about the dedication and skill of our people,” he said.